How does a VSD Pump Cascade System work?

Safe and reliable pump operation for critical cascade pump processes delivers a big jump in performance. Multi-Master support for VLT® AQUA Drive provides full redundancy, effectively ensuring maximum uptime for up to 8 pumps.

Avoid complex systems and PLC programming

Cascade control is a common control system used to control parallel pumps or fans; an activity often performed by a PLC. Cascade for multi-pump operation is chosen due to high level of process management while running the solution more energy efficiently, saving money and reducing CO2 footprint.

Introducing Multi-Master Cascade within the VLT® AQUA Drive enables customers to build less complex systems and avoid PLC programming or avoid PLC altogether by using the drive as a controller. It gives you two unique benefits that effectively simplify and improve the performance of your system:

Reduction in wiring complexity

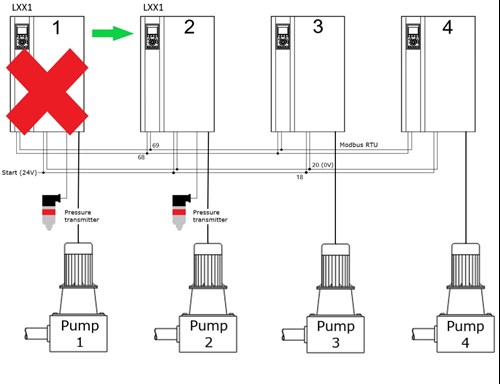

The first advantage is the construction of the entire system without wired logic using the options VLT® Extended Cascade Controller MCO 101 and VLT® Advanced Cascade Controller MCO 102, but instead through the built-in Modbus RTU communication. This solution facilitates the simplification of the entire design process, allowing a simpler wiring diagram and a reduction in wiring complexity, thanks to the use of the terminals of only the RS485 port.

Automatic and intelligent control

The second new feature considers the implementation of the Multi-Master functionality. The multi-master controller for VLT® AQUA Drive FC 202 detects intelligently and automatically when a master device is out of use and immediately delegates the management of the entire equipment to another drive. The use of the VLT® Smart Start feature makes configuration simple and intuitive. The guided procedure is activated from the display, allowing quick and precise configuration of the system.

Take full advantage of the system’s full functionality

The illustration below represents a system of four drives. Two of the drives are assigned as masters and can be identified by the license code LXX1. In the event of a defect on the master ID 1 device, the master automatically switches to ID 2 to continue performing the system’s full functionality until ID 1 is reactivated.

The implementation of these two new features significantly improves system performance in terms of reliability, versatility and functionality.

We are the UK’s Official Water Drive Service Partner providing sales, service and support for the full range of Danfoss VLT AQUA Drives. Email us at [email protected] for all of your Drive needs.

Source: Danfoss VLT® AQUA Drive Pump Cascade 2.0 with Multi-Master support