Top Safety Tips for Electrical Engineers

Introduction

Electricity can kill or severely injure people and cause damage to property. Every year many accidents at work involving electric shock or burns are reported to the Health and Safety Executive (HSE). Most of the fatal incidents are caused by contact with overhead power lines.

Those using or working with electricity may not be the only ones at risk – poor electrical installations and faulty electrical appliances can lead to fire, which may also cause death or injury to others. Most of these accidents can be avoided by careful planning and straightforward precautions.

What are the hazards?

The main hazards are:

- contact with live parts causing shock and burns – normal mains voltage, 230 volts AC, can kill;

- faults which could cause fire; and

- fire or explosion where electricity could be the source of ignition in a potentially flammable or explosive atmosphere.

Most electrical accidents occur because people are working on or near equipment that is:

- thought to be dead but which is live;

- known to be live but those involved do not have adequate training or appropriate equipment to prevent injury, or they have not taken adequate precautions.

Assessing the risk

Your health and safety risk assessment should take into account the risks associated with electricity. It will help you decide what action you need to take to use and maintain your electrical installations and equipment and also how often maintenance is needed.

The risk of injury from electricity is strongly linked to where and how it is used. The risks are greatest in harsh conditions, for example:

- in wet surroundings – unsuitable equipment can easily become live and can make its surroundings live;

- outdoors – equipment may not only become wet but may be at greater risk of damage; and

- in cramped spaces with a lot of earthed metalwork such as inside a tank – if an electrical fault developed it could be very difficult to avoid a shock.

Some items of equipment can also involve greater risk than others. Extension leads are particularly liable to damage – to their plugs, sockets, connections and the cable itself. Other flexible leads, particularly those connected to equipment which is often moved, can suffer from similar problems.

Reducing the risk

Once you have completed the risk assessment, you can use your findings to reduce unacceptable risks from the electrical equipment in your workplace. There are many things you can do to achieve this, and some of them are listed below.

- ensure people working on or with your electrical equipment or systems are ‘competent’ for the task.

- ensure the electrical installation is safe

- provide safe and suitable equipment

- reduce the voltage

- provide a safety device

- carry out preventative maintenance

- work safely

Correct selection and use of equipment

- equipment must be properly designed, constructed, installed and maintained so that it does not present a risk of electric shock, burns, fire or explosion when properly used;

- the user must have sufficient knowledge and experience to recognise the danger and avoid it;

- you must select equipment that is suitable for the environment in which it is used;

- Certified explosion-protected equipment must be used in places where there could be potentially explosive atmospheres;

- You must assess the situation before work is carried out on or near equipment;

- Where possible, you must avoid live working during commissioning and fault finding; e.g. by using suitably designed equipment with in-built test facilities and diagnostic aids.

Assessing safe working practices

The procedure can be divided into four stages as follows:

- deciding whether to work dead or work live;

- planning and preparation for actions which are common to both dead and live working;

- procedures for working dead or

- procedures for working live.

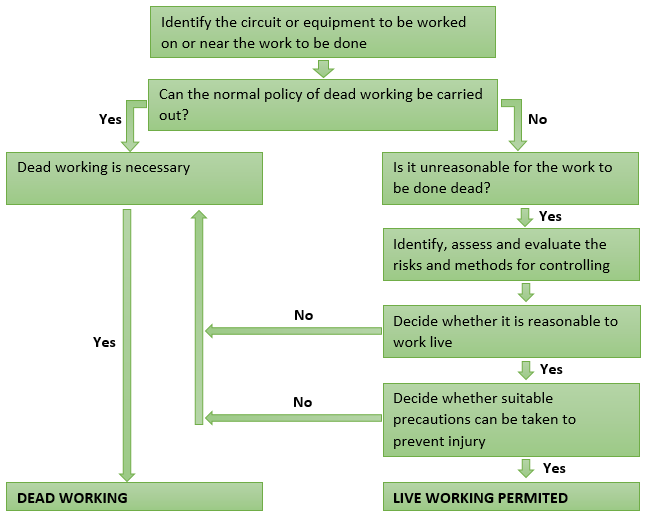

Deciding whether to work dead or live

You should plan and programme the work to allow all jobs to be carried out where possible with the equipment dead. Three conditions must be met for live working to be permitted where danger may arise. If just one of these conditions cannot be met, live working must not be permitted and dead working is essential. The assessment procedure illustrates this. The conditions are:

- it is unreasonable in all the circumstances for the conductor to be dead; and

- it is reasonable in all the circumstances for the person to be at work on or near that conductor while it is live; and

- suitable precautions (including, where necessary, the provision of personal protective equipment) have been taken to prevent injury.

Figure 1. Deciding whether to work dead or live

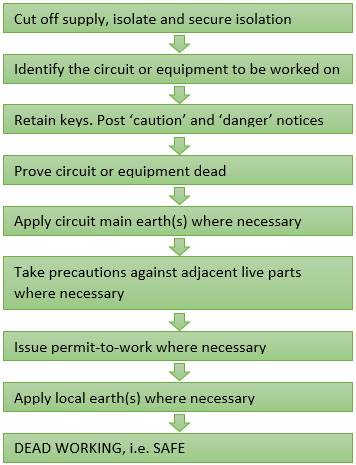

- Working dead

Figure 2. Dead working procedures

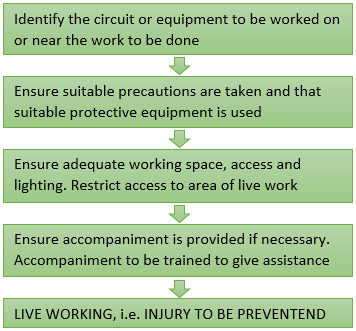

- Working Live

Figure 3. Live working procedures

Source: Health and Safety Executive

http://www.hse.gov.uk/pubns/indg231.pdf

http://www.hse.gov.uk/pUbns/priced/hsg85.pdf